How Big A Concrete Floor Slab Can Be Casted Without Cracks?

- Dr. Zack Lim

- Aug 10, 2021

- 9 min read

This article is to discuss what is the optimum size a concrete floor slab can be casted in a single panel without any cracks and defects especially in the industrial floor sector which demand for high quality floor. Even though the technology behind the construction of concrete slab has improved over the years, besides expecting a floor to be built flat and level, one of the major challenges facing the construction industry is how to built a ‘crack-free slab. Concrete being a vagarious material tends to crack due to various reasons but mainly caused by drying shrinkage, thermal movement and restraints. Therefore, concrete floor cracking may be caused by a single factor but also combination of two or more factors. As such designers and builders can only endeavor to mitigate, minimize, or control cracks but almost impossible to guarantee constructing a large concrete slab with no cracks.

1.0 Why big slabs are preferred?

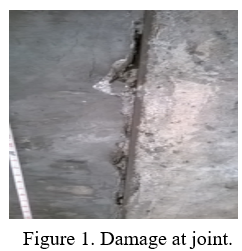

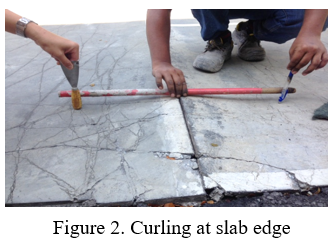

If slabs are casted in smaller panels and without restraints, cracks can easily be avoided but to construct a large size panel, for example 1,000m2 in a single pour successfully without any form of cracks and defects will be a challenge. Large slabs are preferred as it speed up the job, contain less construction joints and contraction joints which are potential weakness on the slab if not properly constructed as shown in Figure 1. The other advantage of minimum joints is to reduce curling of slab at edges as shown in Figure 2. Such curling defects will disrupt smooth operation of lift-trucks and spalling at joints resulting in continuously costly repair.

2.0 Construction of concrete floor slab (slab-on-grade)

Concrete has high compressive strength but low tensile strength and tensile strength of the concrete is only about 10% of the compressive strength, therefore concrete will cracks when the tensile stress within exceeds the tensile strength of the concrete. Hence, one way to mitigate cracks is to lower the tensile stress in concrete and to increase the tensile strength of the concrete. When cracks occurred, blame goes to poor workmanship, poor quality of concrete supplied or improper design. In actual facts, any cracks resulted could be man-made or caused by factors to be discussed as follows.

Common factors which may contribute to cracking in floor slab.

2.1 Ground settlement

Subgrade is the original ground and it is best to carry out a soil investigation to study the soil bearing capacity to support the intended design load. Any filling materials selected for filling low shall be suitable for easy filling and well compaction. A well-compacted sub-base will facilitate loaded vehicles to roam the construction site freely without rutting the surface and also a simple proof rolling method to ensure the subgrade and sub-base are well compacted to prevent settlement cracks.

2.2 Contraction joints

As thicker slab is stiffer and will tend to produce less cracks compared to a thinner one unless the later is specially designed. Likewise, a thinner slab will also tend to curl more than a thicker slab of similar mix design and working condition. Therefore, to avoid random cracking, contraction joints are created on weaken planes on the slab surface at locations where high stresses accumulate and prone to cracks. In fact, contraction joints are simply pre-determine man-made straight line cracks created to release stresses on the floor surface to induce cracks when the slab commence to shrink, being straight line man-made cracks, nobody will complain. If contraction joints are not provided to disipate the stresses, random cracks will be unavoidable.The contraction joints are carry out using mechanical diamond saw machines the next day or the same day if a green blade is available. The depth of cut is normally one-fourth of the slab thickness and the saw-cutting is carried out immediately when the concrete gained sufficient hardnesss, normally between 8 to 12 hr after the floor is finished. To mitigate random cracks, contraction joint spacings of maximum 36 times the slab thickness, up to a maximum of 5.5meter have produced acceptable results(ACI 302.1R-04). If a slab is 150mm thick, the contraction joints need to be spaced at every 5.4meter.

Contradictly, wider contraction joints spacing of up to 16m x 16m have been successfully carried out reinforced with 20kg/m3 of steel fibres without any form of cracks.

2.3 Type of reinforcement and positioning

To select welded mesh or steel bars as reinforcement for crack control is one task but placing and positioning the reinforcement location right is the challenge. The purpose of reinforcement is to provide additional strength where needed and if cracks happened, it supposed to keep the cracks tight and preventing it from opening and becoming wider. If the location of reinforcement is wrongly placed, for example, placed lower than mid section of slab, it will defeat it’s purpose and may not performed. It is best to position about 30mm from the surface for crack control. To overcome such difficult to position the reinforcement right, steel fibres or synthetic fibres are used as a replacement for better crack control. Generally, fibres will provide better crack control as they are 3-dimensionally distributed within the concrete slab to absorb any tensile stresses which occur at early stage when the young concrete has yet to achieve the tensile strength to resist cracks. When early micro-cracks developed, the fibre strand will intersect and blocked the micro-cracks from developing into macro-cracks as the concrete shrinks.

2.4 Concrete mix design

Concrete mix design is of utmost important not only to produce high strength concrete but to achieve good workability, cohesiveness, durability and minimum shrinkage to mitigate cracks. The main cause of cracks resulted from volumetric changes of concrete as the water evaporates gradually resulting in shrinkages.

As a rule of thumb, every 6m of concrete slab, can shrink as much as 3mm, as such it is advisable to use lowest permissible water/cement ratio for the concrete mix design without affecting the workability as water being the single greatest factor affecting shrinkage. Research confirmed that 1% increase in water will increase shrinkage by about 2%. When the concrete is still in the plastic phase, the concrete surface dries and shrinks so rapidly that tensile strain exceed the strain capacity of the young concrete which will results in plastic shrinkage cracks. Designing a concrete mix right with minimum shrinkage of less than 3% will certainly reduce drying shrinkage cracks and with high early strength will avoid early thermal cracks. Another important consideration is the type of cement used as Ordinary Portland Cement (OPC) will achieve initial set faster with early strength compare to supplementary cementitious materials like pulverised fly ash added.

Therefore, one way to design concrete using minimum water without affecting the workability of the concrete by selecting and packing graded fine aggregate, coarse aggregate with selective superplasticizer in the mix. For construction of floor slabs, the recommended cement content using OPC shall be below 400kg/m3 to avoid curling of slab.

2.5 Poor detailing.

Design error and poor detailing will exposed the slab to greater stresses than it can handled, resulting in cracking. For example, cracks propagated from corners of columns (as shown in Fig. 3) was caused by diagonal re-bars being omitted (shown in Figure 4). Such re-entrance corner cracks happen in all floor openings and columns where stress concentration are high.

2.6 Slab size and aspect ratio of width/length

Slabs are generally casted in narrow strip, wide bays or large pour. The recommended aspect ratio of width/length is preferably 1:1 and not to exceed 1:1.5 as mentioned in “Guide for Concrete Floor and Slab Construction”, ACI 302.1R80. Any floor panels with excessive width-to-length ratios as mentioned will tend to crack to release stresses at the mid-panel surface or at locations with excessive stresses. However, this recommended width-to-length ratio could only be extended to 1:2 or more subjected to better understanding of crack control, adding special admixture to reduce stress in concrete like shrinkage compensating admixture.

Conservatively, recommendation of each panel size to be casted as follows.

For slab on grade: External slab, each panel 4.5m x 4.5m with contraction joints.

Internal slab, each panel 6.0m x 6.0m with contraction joints.

For slab on piles: each cast 20m x 20m

For elevated slabs: each cast 20m x 20m

There is no guarantee that no cracking will be observed based on the abovesaid

recommendation as concrete cracks can be considered normal, even though in

practice, there were claims that slabs which were 2 to 3 times larger than above-

mentioned have been done successfully.

2.7 Jointings - Isolation joints, contraction joints, etc

For slab-on grade, casting of slabs can be carried out in large pour within a day

but contraction joints (e.g. 6m x 6m interval) need to be performed to induce cracks

within the slab to avoid random cracking. When the slab gradually shrinks and

contracts, the cutted joints will slowly open up.

As for construction joints for slab-on-grade, dowel bars need to be installed to cater

for load transfer.

As for suspended slabs, all construction joints need the reinforcement bars to be

continuous.

As for slab on piles, movements joints or expansion joints need to be designed at

probably every 30 to 50m to facilitate expansion and contraction due to panel

shrinkage and temperature change.

2.8 Restraints of slab

For a slab on grade floor built on a well-compacted ground with reasonable flatness and levelness will allow the slab to slide freely with the sub-base with no surface restraints. As for suspended slabs, restraints will mainly be from the columns, beams, reinforced walls and openings.

For slab-on-grade there are several forms of restraint that prevent the concrete from shrinking freely in the form of internal or external forces as follows.

i. Internal restraint

Normally for thicker slab (normally about 1 m thick) where thermal cracks can occur due to temperature difference between the surface zone and the internal core of the concrete. The surface of an element will cool faster (contraction) than the hot core (expansion), thus resulting in early thermal cracks and delayed entriquette formation if the temperature difference between the core and the surface exceeds 20◦C.

ii. Surface restraint

The resistance to allow the slab to slide freely onto the existing sub-base can be achieved by better flatness control on the sub-base surface. To further reduce the coefficient of friction between the slab and the sub-base, placing a slip membrane using polyethylene sheets with thickness of 0.25 mm is highly recommended besides acting as a moisture barrier.

iii. End restraint

Cracks often occurs when floor slab is not permitted to move freely especially when the floor reinforcement is tied to walls, beams and columns. For slab-on-grade, it is best to isolate the floor slab from such fixed structures to release any stresses. Likewise, all four ends of a floor panel should be debonded wherever possible from the ground beams or walls.

iv. Edge restraint

When casting strip pour (long and narrow slab) try to avoid casting the entire infill slab (panel between two completed adjacent slab) at one go if it is too long (> 30 meters), alternatively contraction joints if permitted should be allowed to control any transverse cracks.

2.9 Curing

Curing is the process of controlling the rate and extent of moisture loss from

concrete by trapping the water needed for the chemical reaction during cement hydration. Curing allows the concrete to achieve its potential strength and durability. Late curing or no curing is often cited as a major factor that caused surface defects like craze cracks and loss of concrete strength as much as 30%. As such, early and proper curing is essential to achieve the concrete strength needed and to improve abrasion resistance. Finally, to reduce drying shrinkage, proper curing should be carried out for at least 7 days as 80% of ultimate shrinkage is caused by inadequate or no curing.

2.10 Early thermal cracking

During the hydration process when the cement reacts with water, the chemical reaction produces heat. In hot countries, compounded with the direct heat from strong sunlight onto the slab surface, it will caused the temperature of the slab to rise, resulting in thermal volume change which expand the slab. Subsequently, during the night when the concrete cools, it contracts and since the tensile strength of the concrete being relatively low may lead to cracking.

2.11 Shrinkage control

Ordinary Portland Cement concrete shrinks as it dries, this shrinkage if restrained is conducive to cracking. Therefore, to eliminate drying shrinkage cracks, a shrinkage compensating cement is added to make the concrete expand vey slightly (about 0.0045%). This shrinkage compensating cement is designed to provide dimensional stability during the concrete curing period when the young concrete with low tensile strength is susceptible to crack when the tensile stress exceeds it. This shrinkage compensating cement will expand very slightly when added into concrete which compensate the drying shrinkage as it begins to dry. As the concrete sets, it bonds to the steel reinforcement and while the concrete is curing and gaining strength, the expansive reactions provide a slight controlled elongation to the concrete. The bond to the reinforcement steel causes it to be stretched slightly and places the steel in tension. Whilst the reinforcement steel is in tension, the concrete is thus put in slight compression which is favourable.With shrinkage compensating concrete, not only it will minimize cracks but the joint spacing can also be double.

3.0 Conclusion

There is no arbitrary limit on the size of the slab to be poured in a single day if reasonable crack width is allowed and acceptable but to build a large slab without any form of cracking and defects is the biggest challenge.

The maximum size of pour shall be determined by practical considerations such as the followings:

1. Can the concrete supplier provide continuous supply of concrete without any interruption to avoid defects like cold-joints.

2. Does the contractor have sufficient well-trained manpower with good construction practices and technical know-how to execute such large slab.

3. Are there sufficient, “state of art” machinery and equipment to fulfil the objective and meet the specified floor requirement.

In conclusion, to construct a large floor slab without or minimum cracking, a composite concrete system is recommended by adding shrinkage compensating compound, lower water/cement ratio, heavier reinforcement and follow the best construction practices.

Comments